Build Science™ 401

Build Science™ 401 | Episode 1: Basement Slab Foundation Wall Details

The first episode of Build Science™ 401 frames the building envelope as one continuous, integrated system where air, water, vapor, and thermal layers must stay aligned—especially at foundations, penetrations, and transitions. Using a real-world ICF foundation, Matt Risinger and Steve Baczek explain how built-in insulation, rebar, keyways, and monolithic pours work together, alongside smart water management strategies like bagged footings, insulated gravel under slabs, perimeter drains, and ICF-compatible waterproofing. They bust common below-grade myths, showing through blower door testing that the ground can effectively act as an air barrier and that overcomplicating under-slab air sealing often doesn’t improve performance. The discussion also clarifies vapor barriers versus vapor retarders, concrete drying behavior, and risk-based decision making. The core message: details vary, but physics doesn’t—durability and performance come from continuity, compatibility, and assemblies that do multiple jobs well.

Episodes

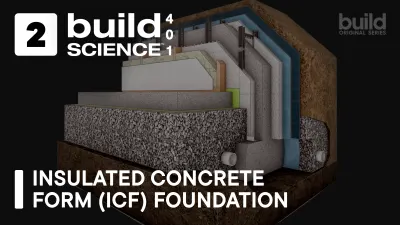

Build Science™ 401 | Episode 2: Insulated Concrete Form (ICF) Foundation

Episode 2

Episode 2 of Build Science™ 401 covers how to build a high-performance foundation by aligning and maintaining continuous control layers for water, air, vapor, and thermal management. Focus on real-world performance over theory for resilience and efficiency.

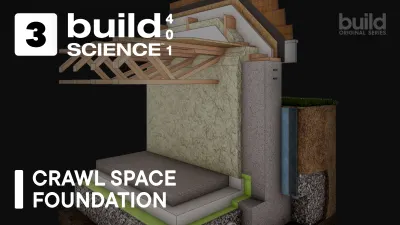

Build Science™ 401 | Episode 3: Crawlspace Foundation

Episode 3

Episode 3 of Build Science™ 401 details a crawlspace or “short basement” foundation using real 2D and 3D drawings to show how water, air, vapor, and thermal control layers must align and remain continuous. Matt & Steve explain how elements like sub-slab insulation, drainage, closed-cell spray foam, and exposed foundation work together to manage moisture, air leakage, energy performance, durability, and region-specific risks like termites and frost depth.

Build Science™ 401 | Episode 4: Slab on Grade Foundation

Episode 4

Episode 4 of Build Science™ 401 walks through the building envelope as a fully integrated system, emphasizing (you guessed it) that continuity of water, air, vapor, and thermal control layers is what ultimately determines durability and performance. Matt and Steve reiterate one of their most common warnings: water is the number one enemy, followed closely by air, and that most “vapor problems” are really failures in water or air management.

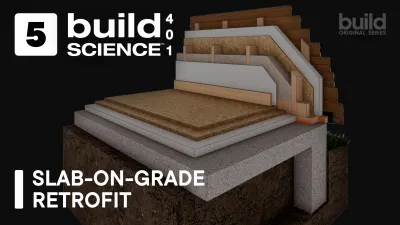

Build Science™ 401 | Episode 5: Slab-on-Grade Retrofit

Episode 5

Episode 5 of Build Science™ 401 episode walks through a slab-on-grade retrofit detail to show how air, water, vapor, and thermal layers must work together as one continuous system for durability and comfort. Matt Risinger and Steve Baczek emphasize managing water and air first—using integrated WRBs, vented rainscreens, elastic sealants, and continuous insulation—so assemblies can drain, vent, and dry instead of trapping moisture.

Build Science™ 401 | Episode 6: Floor Framing & Foundation

Episode 6

On Episode 6 of Build Science™ 401, Matt Risinger and Steve Baczek wrap up their deep dive into floor assemblies and building envelope integration. They emphasize the importance of durability over insulation values in certain areas, explaining why moving insulation to the interior can protect exposed concrete and critical junctions.

Build Science™ 401 | Episode 7: Floor Assembly with Offsite Components

Episode 7

Build Science™ 401 Episode 7 explores how a highly integrated floor and foundation system comes together in an off-site–built home. Matt Risinger and Steve Baczek walk through the use of precast Superior Walls, engineered open-web floor trusses, ZIP-R sheathing, drain-and-vent cavities, and layered air-sealing strategies to manage moisture, airflow, and heat in a challenging, cold, high-moisture site.

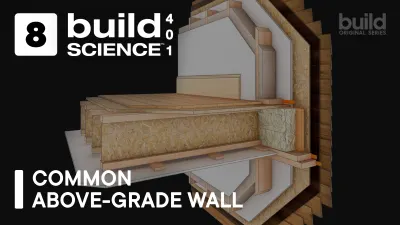

Build Science™ 401 | Episode 8: Common Above-Grade Wall

Episode 8

Build Science™ 401 Episode 8 walks through above-grade wall and floor-to-floor transitions, emphasizing how structural framing, drainage, air, vapor, and thermal layers must remain continuous to create a durable, resilient building envelope. Using a real New England home as a case study, Matt Risinger and Steve Baczek explain why engineered floor systems, rain screens, ZIP System sheathing, and simple, repeatable details reduce risk and improve performance.

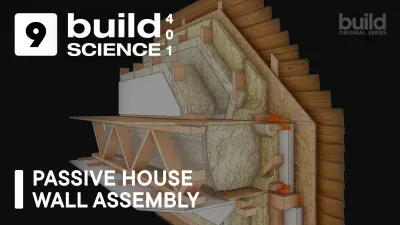

Build Science™ 401 | Episode 9: Passive House Wall Assembly

Episode 9

Build Science™ 401 Episode 9 uses an early Passive House double-stud wall as a retrospective case study to explain how the four control layers must work together as one integrated system. Matt Risinger and Steve Baczek show how ZIP System sheathing was leveraged to do multiple jobs—water, air, and structure—while redundant sealing, staged insulation, and careful blower-door testing were used to confidently achieve the 0.6 ACH50 requirement.

Build Science™ 401 | Episode 10: Passive House Roof Assembly

Episode 10

On Episode 10 of Build Science™ 401, Matt Risinger and Steve Baczek continue to explore how a home’s exterior envelope must integrate air, water, vapor, and thermal control layers for durability and energy efficiency. Using a 2010 coastal New England passive house as a case study, they examine roof assemblies, insulation placement, ventilation paths, and standing seam metal roofing, emphasizing continuity across transitions and critical details like windows, doors, and double-wall assemblies.

Build Science™ 401 | Episode: 11 Vented Roof Assembly

Episode 11

Episode 11 of Build Science™ 401 covers an in-depth discussion on system integration in high-performance building envelopes, specifically on how the four control layers integrate into a vented roof assembly. Matt Risinger and Steve Baczek explain how various layers are connected to create continuous air and vapor barriers, while vented roof assemblies and baffles ensure proper airflow and drying potential.

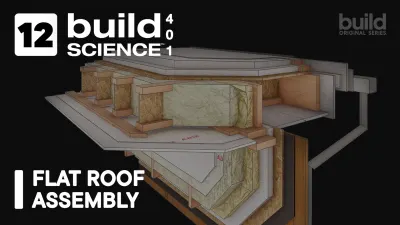

Build Science™ 401 | Episode 12: Flat Roof Assembly

Episode 12

Build Science™ 401 concludes with Episode 12 where Matt Risinger and Steve Baczek review flat roof design, insulation strategies, vapor profiles, and the importance of coordinated detailing between trades to ensure durability and performance. They cover details of a flat roof, including slope, insulation, membrane protection, drip edges, lack of parapets, and roof overhangs, with practical reasoning for each design choice.

Share on facebook

Share on facebook Tweet

Tweet Email

Email Share on Linkedin

Share on Linkedin